Vietnam National University of FORESTRY (VNUF)

Le Xuan Phuong, Phan Duy Hung, Nguyen Thi Minh Nguyet, Cao Quoc An, Ngo Duy Bach, To Thi Thom, Vietnam National University of Forestry, Vietnam

The FOREST project experienced 2 unexpected problems with the Covid-19 pandemic led to social distancing and no mobility was done, then Ukraine war led to the exclusion of Russian partners in the FOREST consortium and the 2 new Vietnamese HEIs participation in mid-2023. VNUF joined the FOREST project from the beginning and has to overcome these obstacles to complete the project as its deadline is January 14, 2024. Although no overseas exchange activity for VNUF’s teachers and students was designed to help us strengthen our capacity, some online activities such as online training with IPT (Portugal) in January 2024 and MUL (Austria) have helped us a lot to communicate with experienced teachers from Europe and exchanged with them the best practices to develop a European standard high-quality MSc program based on the Bologna process standards, but also new and updated T&L&A techniques for teachers and curriculum design with MUL colleagues at the offline training in HCMUTE, Vietnam in November 2023.

As the leading training and research centre in the fields of forestry, natural resources, environment, disaster mitigation and prevention in Vietnam, thereby contributing to the sustainable development of the economy, society and environment, we, VNUF, integrate into our existing MSc program on Forest products engineering with the chemical solutions that may help to increase the income value of the local people via sustainable livelihood such as medicinal plants, forest products food, biomass energy including wood pellets and charcoal, wood composites as high-quality wood-based materials. Additionally, the aspects of LCA and sustainability sciences will be taught to raise awareness of furniture producers about the importance of reducing waste and energy to lower the impact on the environment for the manufacturing sector both in the processing, during using the product and after the life cycle.

I. The FOREST Master program at VNUF:

A TNA (Training Need Assessment) has been carried out to identify the knowledge, skills and competencies that labour market demand in the next 5 years when the students complete the Master programme via asking the employers, research institutes, companies, universities/ colleges, NGO, young students who will be future Master students. A gap identified helps our university to fill in the current training program to develop a new FOREST master program with “future-oriented chemistry”. VNUF has developed a competency-based curriculum in line with Bologna provisions. We have learnt EU best practices in university-business partnerships aimed at providing students with real cases. The Forest and Climate change module has raised awareness of climate change impact and consequences for the future among business structures and communities, especially Vietnam is one of the world’s top five most vulnerable countries to climate change. Typhoons, floods, droughts, and landslides frequently threaten a high proportion of the country’s 100+ million people and economic assets concentrated along its long, densely populated, coast. Forest is considered a nature-based solution for climate change (@FAO). Forestry practices include planting new forests, allowing forests to regrow naturally where they have been cut down, and improving forest management.

The new FOREST Master program at the Vietnam National University of Forestry fits well with the mission and vision of our university and our non-stop efforts to work towards a Greener Vietnam with resilient forests, landscapes, and communities.

Figure 1. The concept of the new FOREST MSc program at VNUF

1. Master’sProgram:ForestproductsEngineering Code: 8.54.90.01

2. Objectives:

- This master training program provide in-depth theoretical knowledge, high practical skills, the ability to do independent research, guide scientific and professional research, work creatively and have the ability to discover, solve new problems in the field of science and technology of forest product processing

3. Learning Outcomes:

| I. | Knowledge | |

| PLO1 | Basic understanding of Philosophy | |

| PLO2 | Have basic knowledge of English according to regulations of the Ministry of Education and Training | |

| PLO3 | Have basic knowledge of Scientific Research Methods, Applied Wood Science, Cutting Tools in Woodworking, Wood Chemistry, Glues and Coatings, Electronics and Automatic Control, Forests and Climate Change,…. | |

| PLO4 | Have knowledge of modern woodworking equipment. | |

| PLO5 | Have knowledge of wood processing technology, drying technology, wood quality improvement technology, surface finishing technology of wood materials, composite materials, automation of production processes, forest product chemistry, and use non-timber forest products such as medicinal plants, food, and biomass energy. | |

| PLO6 | Have knowledge about quality management of wooden furniture production, organization of wood processing production, selection and use of wood processing machines, product life cycle assessment, sustainable science. | |

| II. | Skills | |

| PLO7 | Inspect and assess the quality of wood, wood materials and wood products. | |

| PLO8 | Use effectively and improve wood processing machines, equipment and automation lines in wood and non-wood forest product processing factories. | |

| PLO9 | Proficient in drying technology, wood processing technology and wood materials, wood material surface decoration technology, exploitation and post-harvest preservation technology of non-wood forest products. | |

| PLO10 | Organize, direct and manage production activities at wood processing factories, supervise and construct wood projects, organize research and technology transfer activities on wood and forest product processing. | |

| PLO11 | Able to communicate and work in English. | |

| PLO12 | Proficient in using information technology tools in professional and social activities. | |

| PLO13 | Have social communication and teamwork skills. | |

| III. | Attitudes | |

| PLO14 | Have good moral qualities and a healthy lifestyle. | |

| PLO15 | Love your job, be honest and have a high sense of discipline at work. | |

| PLO16 | Strictly comply with country laws and regulations of organizations. | |

| PLO17 | Have a sense of self-awareness and responsibility towards work, the team, yourself and the community. | |

| PLO18 | Have an industrial style and serious working attitude. | |

| PLO19 | Have a spirit of community service, integration and international cooperation. | |

| PLO20 | Be conscious of self-study, practice and update knowledge. | |

| PLO21 | Have a sense of creative thinking. | |

| PLO22 | Graduates from the Master’s program in Forest Products Engineering will meet the English proficiency according to regulations of the Ministry of Education and Training. | |

| PLO23 | Graduates from the Master’s program in Forest Products Engineering will meet the basic information technology application level according to Circular No. 03/2014/TT- BTTT dated March 11, 2014 of the Ministry of Information and Communications. |

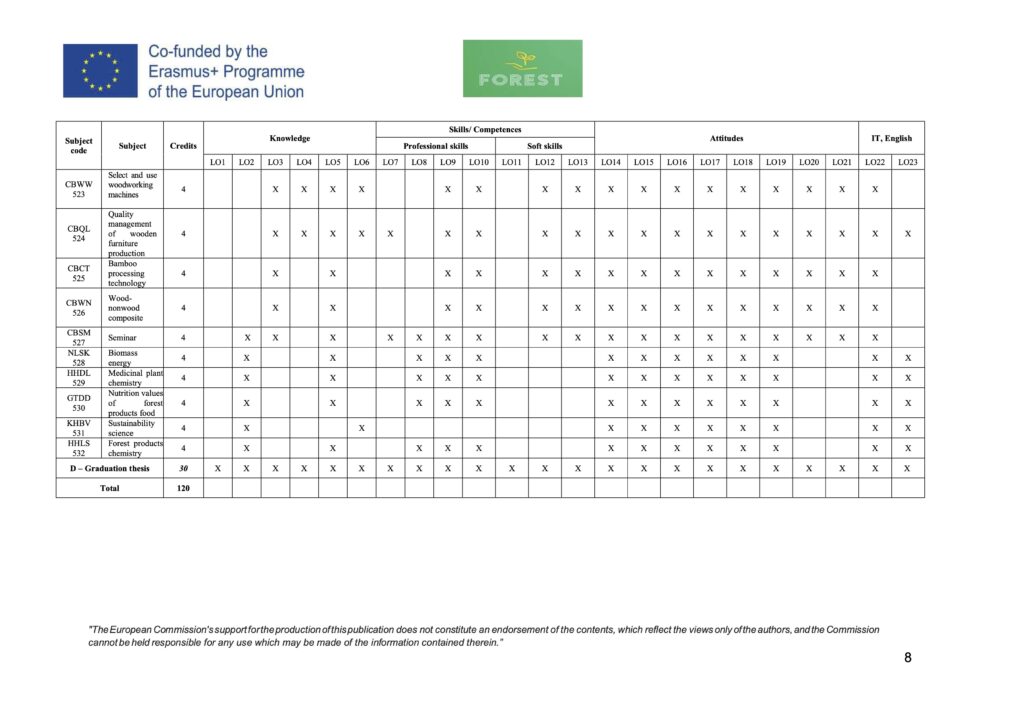

4. List of subjects:

| Text | Number | Subjects | ECTS |

|---|---|---|---|

| I. General knowledge | 12 | ||

| FUTH | 501 | Philosophy | 6 |

| FUTA | 502 | English | 6 |

| II. Basic knowledge | 28 | ||

| Compulsory | 12 | ||

| CNNC | 503 | Research methodology | 4 |

| CBKG | 504 | Applied wood science | 4 |

| CBCG | 505 | Wood cutting tools | 4 |

| Electives (select 16 ECTS) | 16/32 | ||

| CBTU | 506 | Modeling and optimization of technological processes | 4 |

| CBĐL | 507 | Measurement fundamentals | 4 |

| CBKD | 508 | Wood adhesives and coatings | 4 |

| CBHG | 509 | Wood chemistry | 4 |

| CBĐT | 510 | Electronics and automatic control | 4 |

| CBCH | 511 | Technological process and chemical equipment | 4 |

| BDKH | 512 | Forest and Climate change | 4 |

| DGVD | 513 | Life cycle assessment | 4 |

| III. Professional knowledge | 50 | ||

| Compulsory | 30 | ||

| CBTB | 514 | Modern woodworking equipment | 6 |

| CBXG | 515 | Modern wood processing technology | 4 |

| CBSG | 516 | Forest product drying technology | 4 |

| CBVL | 517 | Technology to improve wood quality | 6 |

| CBBT | 518 | Wood composites | 6 |

| CBTS | 519 | Technology for finishing the surface of wood materials | 4 |

| Electives (select 20 ECTSs) | 20/52 | ||

| CBĐG | 520 | Organization of wood production and processing | 4 |

| CBHH | 521 | Wood chemical processing technology | 4 |

| CBTĐ | 522 | Automation in forest product processing | 4 |

| CBWW | 523 | Select and use woodworking machines | 4 |

| CBQL | 524 | Quality management of wooden furniture production | 4 |

| CBCT | 525 | Bamboo processing technology | 4 |

| CBWN | 526 | Wood-nonwood composite | 4 |

| CBSM | 527 | Seminar | 4 |

| NLSK | 528 | Biomass energy | 4 |

| HHDL | 529 | Medicinal plant chemistry | 4 |

| GTDD | 530 | Nutrition values of forest products food | 4 |

| KHBV | 531 | Sustainability science | 4 |

| HHLS | 532 | Forest products chemistry | 4 |

| IV. Graduation thesis | 30 | ||

| Total | 120 | ||

6. Description of subject

6.1. General knowledge

Philosophy (Code: FUTH501; Credits: 6):

According to the regulations of the Ministry of Educaion and Training.

English (Code: FUTA502; Credits: 6):

The English program is designed towards the domestic TOEFL exam with a total score of TOEFL ITP 450, iBT 45 or equivalent…

6.2. Basic knowledge

Research methodology (Code: CNNC503; Credits 4)

The Research Methodology module provides students with basic knowledge of scientific research methodology; Scientific research issues in the field of forestry; Methods of developing scientific research topic outlines; Methods of writing scientific reports; Empirical modeling theory; experimental optimization methods; Apply some specialized software for experimental research.

Applied wood science (Code: CBKG504; Credits 4)

The Applied Wood Science module is the professional basis of the industry and includes a number of main contents: anatomical structure of coniferous and broadleaf wood; The relationship between structure, processing and use of wood; the relationship between wood and water; deformation and plasticity of wood; wood quality; Classification and use of wood.

Wood cutting tools (Code: CBCG505; Credits 4)

The module introduces knowledge about cutting knives, the nature and methods of analyzing the dynamics of the wood cutting process, the quality of the cutting process, methods of finding and solving research problems in cutting.

Modeling and optimization of technological processes (Code: CBTU506; Credits 4)

The module includes the following main contents: Theoretical basis of modeling; Modeling technological processes in wood processing; Solve optimization problems on models; Research direction to develop modeling and optimization of wood processing technology processes.

Measurement fundamentals (Code: CBĐL507; Credits 2)

The Measurement Fundamentals module presents the following basic issues:

- General concepts, quantities and units.

- Types of measurement errors and measurement uncertainties

- Methods and procedures when measuring

- Some main measuring tools.

Wood adhesives and coatings (Code: CBKD508; Credits 2)

The module presents the following issues: 1- Overview, 2- Theory of bond formation, 3- Use of glues, coatings, and coatings in forest product processing, 4- Modification of glue, coating, 5- Determine some properties of jewelry adhesives and films.

Wood chemistry (Code: CBHG509; Credits 4)

The module includes knowledge about the structure and basic properties of chemical components in wood and fibrous plants: Lignin, Cellulose, carbohydrates, extractive substances and other components. The influence of wood chemical components in the processing of wood materials.

Electronics and automatic control (Code: CBĐT510; Credits 4)

The Electronics and Automatic Control module will equip students with the most necessary knowledge and skills to search and update information. The content of the course focuses on three main parts: the first part presents basic semiconductor elements, algorithmic circuits and common microprocessors in control problems; Part two is the applications of specialized PLC programmable controllers; The final content is the method of analyzing a general data collection, control and processing system, and the choice of optimal solutions for some practical applications.

Technological process and chemical equipment (Code: CBCH511; Credits 4)

The module includes knowledge about the principles of processes, separation of heterogeneous systems, mass transfer (distillation, absorption, adsorption, extraction, concentration). Structure and operating principles of basic equipment in chemical processing and influencing factors.

Forest and Climate change (Code: BĐKH512; Credits 4)

This module provides basic concepts/knowledge about forests, climate change and the role of forests, a nature-based solution to adapt and minimize the impact of climate change, especially in the Vietnamese context, one of the countries most affected by climate change in the world. The richer the forest, the more carbon it stores, and the higher its biodiversity, the greater its role in minimizing the negative impacts of climate change. Sustainable forest development contributes positively to the Prime Minister’s goal of net zero emissions by 2050 at COP26.

Life cycle assessment (Code: ĐGVĐ513; Credits 4)

This module provides basic knowledge and skills about the life cycle of wood products, as well as assessing the environmental impact during product production, use and disposal after the end of the life cycle. Students have the skills to evaluate the life cycle of a typical wood product.

6.3. Professional knowledge

Modern woodworking equipment (Code: CBTB514; Credits 6)

The module introduces theoretical knowledge about structure, working principles, processes and operating techniques of modern machines in wood processing while also building proficient skills in disassembly, maintenance and programming. and operate modern woodworking machines.

Modern wood processing technology (Code: CBXG515; Credits 4)

The module introduces theoretical knowledge about modern wood processing technologies (modern processes and techniques used in wood processing), and at the same time builds proficient practical skills in operating machines and tools. Modern wood processing line.

Forest product drying technology (Code: CBSG516; Credits 4)

The module provides in-depth knowledge about lumber drying technology, some special drying methods, veneer drying technology, wood chip drying technology, energy and drying costs.

Technology to improve wood quality (Code: CBVL517; Credits 6)

The module provides knowledge about the concept of wood quality, factors affecting wood quality; Overview of improving wood quality; Wood modification technology includes the following types of technology: chemical modification of wood; thermal modification of wood; modified wood impregnation; Wood treatment technology: wood discoloration treatment technology; plasticization treatment; treatment to improve biological durability.

Wood composites (Code: CBBT518; Credits 6)

The module provides students with knowledge about: concepts, characteristics, applications and development history of some types of wood composite materials; production technologies of Glulam, structural composite lumber (SCL); At the same time, providing skills in calculating technological parameters to produce wood composite materials; Check the quality of raw materials and wood composite products.

Technology for finishing the surface of wood materials (Code: CBTS519; Credits 4)

This subject provides knowledge on finishing technology for wooden furniture surfaces with liquid coatings: pneumatic method, electrostatic method, high pressure method, contact method; Finishing technology for panels: gluing wood veneer, gluing impregnated paper, gluing synthetic veneer, gluing decorative laminates; Methods of testing and evaluating the quality of finishing layer.

Organization of wood production and processing (Code: CBĐG520; Credits 4)

Production process and structure of wood processing factory, modern wood processing production management systems, methods of testing and evaluating the quality of wood and wood products; quality control in some types of wood processing technology; Inventory and handle products with technical defects and remedial measures.

Wood chemical processing technology (Code: CBHH521; Credits 4)

This subject provides knowledge on raw materials, technological process for producing semi-finished fiber products, advanced pulp production technology, Cellulose chemistry, wood hydrolysis technology. Chemical modification of wood.

Automation in forest product processing (Code: CBTĐ522; Credits 4)

This subject includes the main contents: General problems of production process automation; Basic elements and equipment in automatic systems; Conventional and advanced automatic adjustment and control systems; Automating technological processes of forest product processing. Research and development direction of production process automation.

Select and use woodworking machines (Code: CBWW523; Credits 4)

This subject includes the main contents: Machine technical level, machine quality indicators and assessment methods, procedures for evaluating machine technical level; Use machines and standards for effective use of machines and equipment; Research direction on effective use of machines in modern production.

Quality management of wooden furniture production (Code: CBQL524; Credits 4)

This subject provides students with basic knowledge of quality management, introducing quality management systems according to standards (ISO 9000, TQM, Q- Base), and methods. Manage Six Sigma and provide inspection methods, tools, quality control and assessment techniques commonly used in wooden furniture manufacturing.

Bamboo processing technology (Code: CBCT525; Credits 4)

This subject includes the following basic contents: Characteristics and properties of bamboo, processing technology for common bamboo products, technology for producing artificial bamboo boards, technology for processing bamboo products. Special products from bamboo.

Wood-nonwood composite (Code: CBWN526; Credits 4)

The subject includes the following 3 main contents: (1) Overview of wood-nonwood composite materials; (2) Technology for producing inorganic binding materials; (3) Technology for producing wood-plastic composite materials.

Seminar (Code: CBSM527; Credits 4)

This subject provides students with practical knowledge about the fields of wood processing in production and trade: raw materials, products, production technology, market and production management.

Biomass energy (Code: NLSK528; Credits 4)

This module provides knowledge and skills about biomass energy, typical forms of biomass raw materials (pellets and charcoal; activated carbon), production technology and product quality criteria and its quality control.

Medicinal plant chemistry (Code: HHDL529; Credits 4)

This module provides knowledge and skills to recognize and evaluate the quality of medicinal herbs under typical forest canopy with high economic and commercial value, understand the medicinal properties of selected medicinal herbs and introduce post-harvest processing/preservation technologies to ensure quality of raw materials for subsequent deep processing stages to produce medicine.

Nutrition values of forest products food (Code: GTDD530; Credits 4)

This module provides knowledge and skills to recognize and evaluate the quality and nutrition values of typical forest foods with high economic and commercial value, and introduce post-harvest processing/preservation technologies to ensure the quality of raw materials for the next stages of food processing.

Sustainability science (Code: KHBV531; Credits 4)

This module provides basic knowledge and skills in sustainability science, sustainable development goals (SDGs) and Economic, Environmental and Social aspects. Benefits of green growth; Sustainability in the chemical industry; 12 principles of Green Chemistry; Supports the integration of environmental and social regulations into core business activities.

Forest products chemistry (Code: HHLS532; Credits 4)

This module concentrates on the chemical uses of non-wood forest products. It outlines the traditional products such as rosin, turpentine, tannin extracts, cinnamomum bark, essential oils and shellac, as well as pharmaceutical and health products.

II. The Center of Excellence:

VNUF develop innovative LLL modules in terms of content focusing on the chemical processing of forest products and T&L resources and delivers them in short training/ seminar format, and through policy workshops. A new structural unit is introduced to enhance the consulting, education and research capacity of VNUF: centres of excellence in future-oriented chemistry. The centre is embedded into the university structure (within the wood chemistry lab, Wood industry and Interior design college (WIID), VNUF); they will provide expertise on chemical uses of medicinal plants and forest products foods as climate change mitigation techniques and solutions for Vietnam thus contributing to science-based decisions in the environmental and sustainability sphere. The center was established in 2023 and has been home for WIID students to do experiments and research on wood and forest products chemistry since then.

III. The summer schools

The 2023 summer school was organized in hybrid mode to promote the new MSc programs developed by 4 Vietnamese HEIs to 68+ undergraduate students both online and offline in late August and the beginning of September. The lectures from both European HEIs professors and Vietnamese HEIs professors create a unique one-week training for students in Vietnam. The students’ positive feedbacks encourage us to continue our work to improve the training program and inspire them with new programs and offer them the competencies that the job market requires. This also creates a “common language” between students and teachers to better understand young students’ desires and the soft skills gap. Furthermore, a social network between students from 4 HEIs located in the North (TNUS and VNUF), Central (HUSC) and South (HCMUTE) of Vietnam is created to strengthen their capacity via this networking and social and academic exchange activities later on.